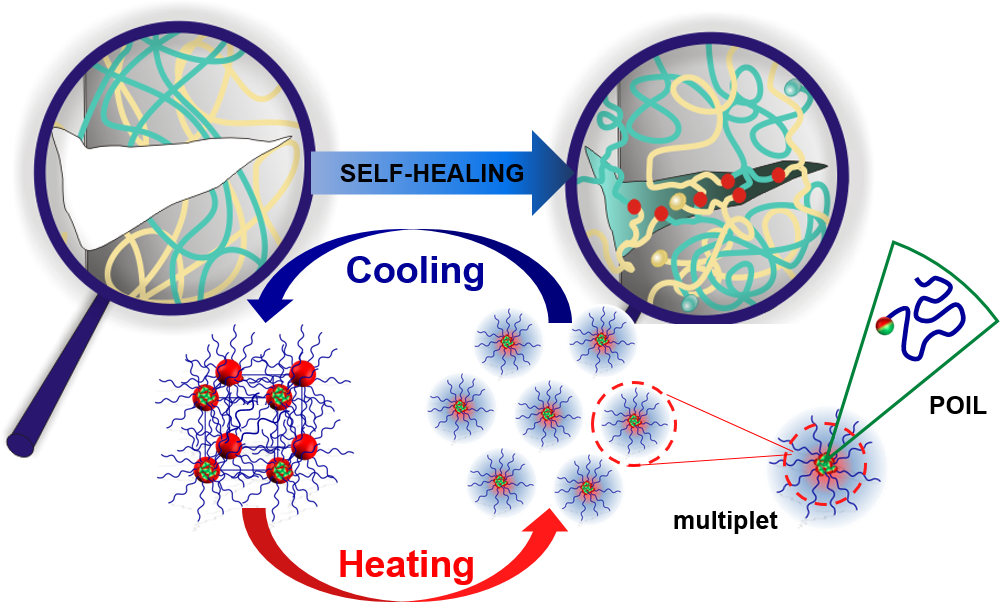

Improved charge-transport and the compensation of volume-changes is crucial in technology of modern batteries, fuel-cells and transistors. Several EU/DFG-funded projects (Bat4ever within Horizon-2020, DFG) do address the chemical synthesis of novel ionomers and ionogels, used as electrolytes within large international consortia. Novel long living batteries and transistors with self-healing functions are prepared and studied as future technologies. Novel polymeric ionic liquids1-4 are studied aiming to increase ionic conductivity,1, 2 charge-transfer to the electrodes and enable a longer lifetime of the final batteries. Knowledge of ionic mobilities is transferred to interfacial transport processes such as ionic liquid gating,5 where the underlying interface and its structural changes are studied. We recently have developed self-healing and 3D-printable electrolytes.6-8

References

- Frenzel, F., et al., Molecular Dynamics and Charge Transport in Polymeric Polyisobutylene-Based Ionic Liquids. Macromolecules 2016, 49 (7), 2868-2875, DOI:http://dx.doi.org/10.1021/acs.macromol.6b00011.

- Frenzel, F., et al., Glassy Dynamics and Charge Transport in Polymeric Ionic Liquids. In Dielectric Properties of Ionic Liquids, Paluch, M.; Kremer, F., Eds. Springer International Publishing Switzerland 2016; pp 115-129, DOI:10.1007/978-3-319-32489-0_5.

- Appiah, C., et al., Hierarchically Mesostructured Polyisobutylene-Based Ionic Liquids. Macromolecular Rapid Communications 2016, 37 (14), 1175-1180, DOI:http://dx.doi.org/10.1002/marc.201600020. Osim, W., et al., Surface modification of MoS2 nanoparticles with ionic liquid-ligands: towards highly dispersed nanoparticles. Chemical Communications 2013, 49 (81), 9311-9313, DOI:http://dx.doi.org/10.1039/C3CC45305G. Aswath, P., et al. Synergistic mixtures of ionic liquids with other ionic liquids and/or with ashless thiophosphates for antiwear and/or friction reduction applications. 2013, DOI:http://www.google.com/patents/US20130331305. Zare, P., et al., Hierarchically Nanostructured Polyisobutylene-Based Ionic Liquids. Macromolecules 2012, 45 (4), 2074-2084, DOI: https://pubs.acs.org/doi/full/10.1021/ma202736g. Pagano, F., et al., Dicationic ionic liquids as lubricants. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 2012, 226 (11), 952-964, DOI:https://doi.org/10.1177%2F1350650112458873.

- Stojanovic, A., et al., Designing melt flow of poly(isobutylene)-based ionic liquids. Journal of Materials Chemistry A 2013, 1 (39), 12159-12169, DOI:http://dx.doi.org/10.1039/C3TA12646C.

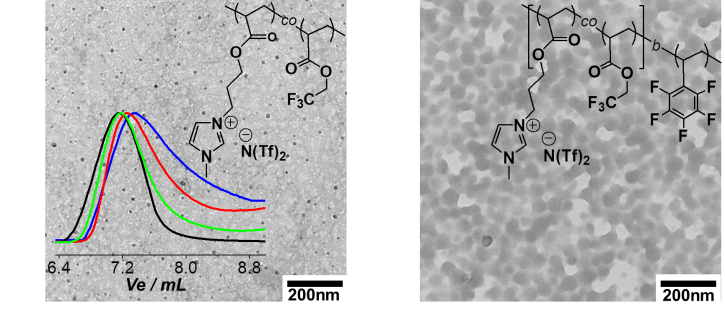

- Chen, S., et al., Synthesis and Morphology of Semifluorinated Polymeric Ionic Liquids. Macromolecules 2018, 51 (21), 8620-8628, DOI:https://doi.org/10.1021/acs.macromol.8b01624. Chen, S., et al., Gating effects of conductive polymeric ionic liquids. Journal of Materials Chemistry C 2018, 6 (30), 8242-8250, DOI:http://dx.doi.org/10.1039/C8TC01936C.

- Rupp, H., et al., 3D Printing of Solvent-Free Supramolecular Polymers. Frontiers in Chemistry 2021, 9, 771974, DOI:https://doi.org/10.3389/fchem.2021.771974.

- Katcharava, Z., et al., 3D Printable Composite Polymer Electrolytes: Influence of SiO2 Nanoparticles on 3D-Printability. Nanomaterials 2022, 12 (11), 1859, DOI:https://doi.org/10.3390/nano12111859.

- Rupp, H., et al., Printable Electrolytes: tuning 3D printing by multiple hydrogen bonds and added inorganic lithium-salts (LiTFSI). Advanced Materials Technology 2022, 7(8), 2200088, DOI:https://doi.org/10.1002/admt.202200088.